Understanding the Role of Shim Plates

Shim plates, often called shims, are essential in many industries. These slim, flat pieces, typically made from metal or plastic, serve as adjusters of space or alignment between two components. Their primary function is to serve as a spacer, adjusting gaps or minor discrepancies that can emerge due to manufacturing variances, wear, or settling. For example, if a machine part is misaligned because of wear, a shim plate can help fill the void, ensuring the machine's smooth function.

Common Types of Shim Plates

Shim plates come in various shapes, sizes, and materials, each suited to a specific application. Here are some of the most common types:

Slotted Shims: These are often rectangular with a slot in the centre. They're commonly used in machinery and assembly lines for easy insertion without disassembling the entire machine.

Solid Shims: Lacking slots, they're used when full surface coverage is required.

Tapered Shims: With one end thinner than the other, they're ideal for applications where a gradual change in thickness is necessary.

Laminated Shims: These are composed of multiple thin layers that can be peeled off to achieve the desired thickness.

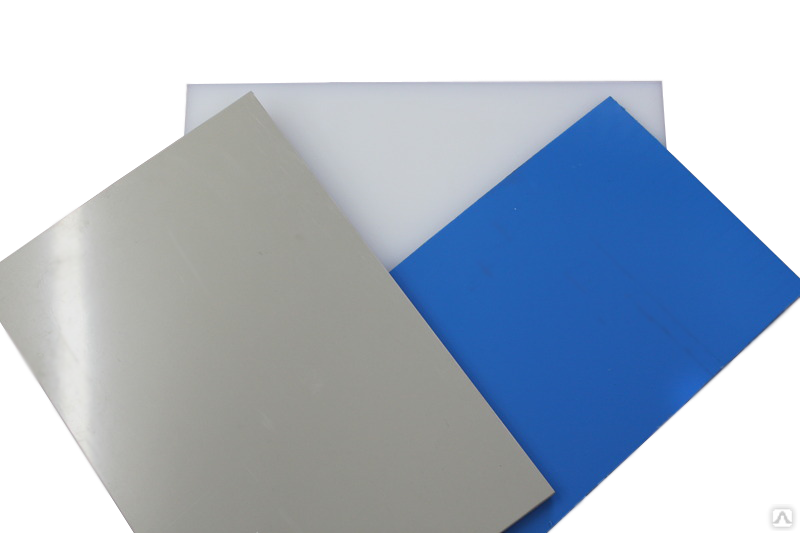

Materials Used for Shim Plates

The material chosen for shim plates often depends on its purpose and the environment it will operate. Frequently used materials are metal, including steel, stainless steel, brass, and aluminium, ideal for heavy-duty tasks. Plastic shims, on the other hand, are corrosion-resistant, making them suitable for chemically active environments. Composite shims combine multiple materials to balance durability and flexibility.

Industry Applications of Shim Plates

Shims find use in a multitude of sectors. In construction, they level and align components during window installations or large machinery setups. The manufacturing sector depends on them on assembly lines where machine alignment directly impacts product quality. The automotive industry employs shims for optimal vehicle assembly alignment, thus reducing wear and enhancing performance. Aerospace, an industry where precision is non-negotiable, uses shims to maintain exact alignment and spacing for various aircraft parts.

Future Trends and Insights

The trajectory of shim plates is evolving with technological advancements. As digital manufacturing techniques, such as 3D printing, gain traction, there's an increasing demand for more precise, custom-made shims. This trend will likely intensify as industries advance to full automation and emphasize precision engineering. In these contexts, ensuring frictionless operations, shims will play an even more crucial role.