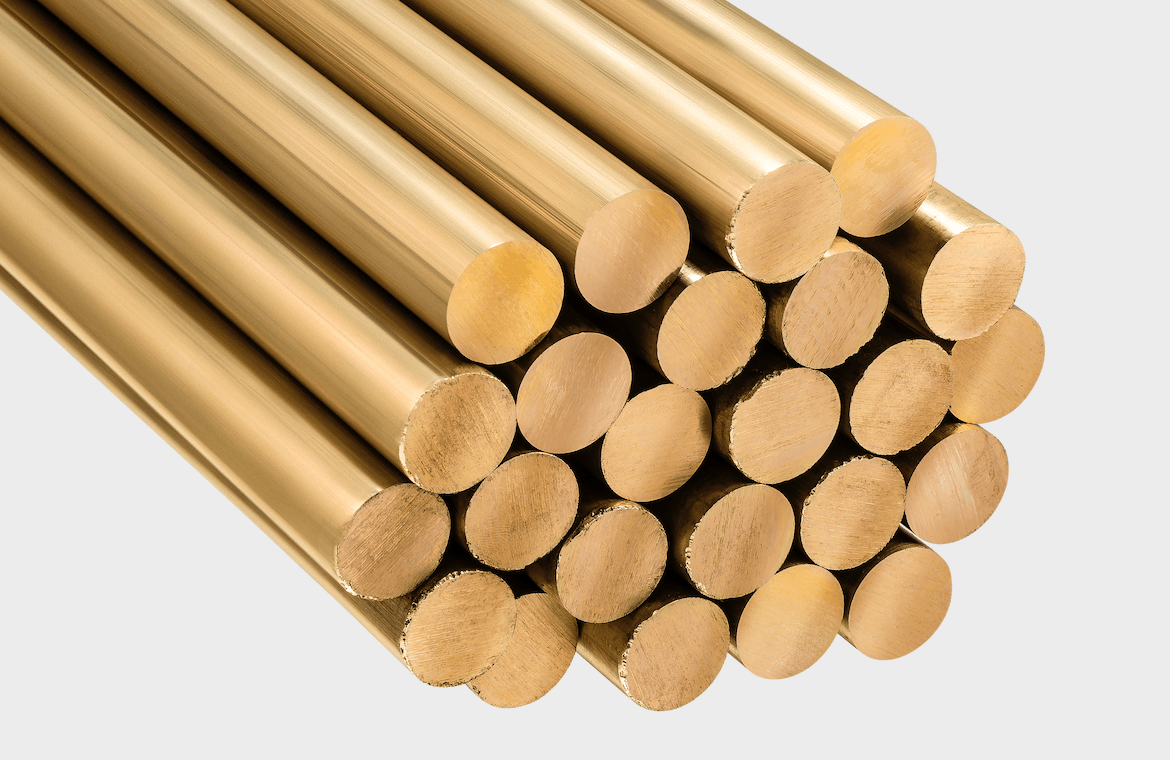

Leaded bronze bars have been a critical material in various industries for centuries. Their unique combination of copper, tin, and lead imparts exceptional mechanical properties, making them valuable for various applications. In this article, we will explore the hidden potential of leaded bronze bars, exploring their remarkable features, applications, and benefits. From historic uses to modern innovations, this guide will provide an in-depth understanding of why leaded bronze bars remain indispensable in manufacturing.

Unveiling the Hidden Potential

Leaded bronze bars possess many properties that make them stand out as a versatile material. Let's explore the key features that contribute to their hidden potential:

High Machinability and Formability

Leaded bronze bars are known for their excellent machinability and formability. Lead in the alloy lowers friction during machining, resulting in smoother operations. This characteristic makes leaded bronze bars preferred for intricate designs and complex components in various industries.

Superior Wear Resistance

Adding lead to bronze enhances its wear resistance, making it an ideal material for friction-related parts, such as bearings, bushings, and gears. The wear-resistant nature of leaded bronze ensures longevity and minimal maintenance in demanding applications.

Self-Lubricating Properties

One of the most remarkable attributes of leaded bronze bars is their inherent self-lubricating properties. This unique feature allows them to function exceptionally well in applications without needing external lubrication. Consequently, leaded bronze bars are widely used when access to regular maintenance is challenging or costly.

High Corrosion Resistance

Leaded bronze bars exhibit high corrosion resistance, making them suitable for marine environments, chemical processing, and other corrosive applications. The protective oxide layer formed on the surface of the alloy prevents degradation, ensuring long-term performance.

Excellent Electrical Conductivity

The copper content in leaded bronze imparts excellent electrical conductivity to the material. As a result, leaded bronze bars are frequently employed in electrical connectors, switches, and other electrical components where efficient current flow is essential.

Optimal Thermal Conductivity

With good thermal conductivity, leaded bronze bars efficiently transfer heat, making them valuable in heat exchangers, radiators, and other heat dissipation applications.

Biocompatibility and Lead-Free Options

In specific formulations, leaded bronze bars can be tailored to meet biocompatibility requirements, making them suitable for medical and dental applications. Moreover, lead-free alternatives have been developed to cater to environmental concerns, further expanding the potential applications of this material.

Customizable Alloys for Specific Needs

Leaded bronze alloys can be customized by adjusting the proportions of copper, tin, and lead to suit specific needs. This versatility allows manufacturers to fine-tune the material properties, making it adaptable for diverse applications.

Applications of Leaded Bronze Bars

Leaded bronze bars' versatility and exceptional properties have resulted in widespread adoption across various industries. Let's explore some of the key applications where these bars excel:

Bearings and Bushings

Leaded bronze bars are widely used in manufacturing bearings and bushings due to their self-lubricating properties and wear resistance. They provide smooth operation and prolonged service life in rotating machinery.

Gears and Worm Wheels

The superior wear resistance and machinability of leaded bronze make it an excellent choice for gears and worm wheels in machinery, ensuring efficient power transmission and reduced friction.

Marine Hardware

Leaded bronze's high corrosion resistance and ability to withstand harsh marine environments make it a preferred material for marine hardware like propellers, marine pumps, and ship fittings.

Electrical Components

Due to its exceptional electrical conductivity, leaded bronze is utilized in various electrical components, including connectors, switches, and terminals, ensuring reliable current flow.

Heat Exchangers

The optimal thermal conductivity of leaded bronze bars makes them a top choice for heat exchangers and radiators in various industrial applications.

Musical Instruments

Leaded bronze bars have been historically employed in musical instruments like cymbals due to their excellent acoustic properties, providing rich and resonant tones.